Bicycle Components Manuals

Manuals

Bicycle Components Manuals

Overview

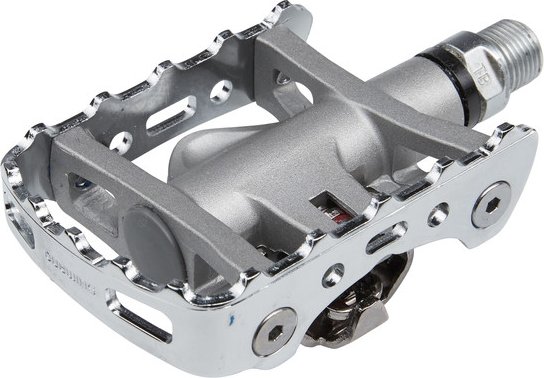

Bicycle components manuals are detailed, authoritative documents that explain the design, operation, maintenance, assembly, troubleshooting, and safety information for the parts and subsystems of a bicycle. These manuals cover a wide range of components including drivetrains (chains, chainrings, cassettes, derailleurs), braking systems (rim brakes, disc brakes, hydraulic and mechanical systems), wheels and hubs, suspension systems (forks and rear shocks), headsets and handlebars, seatposts and saddles, pedals and cranks, steering systems, and electronic groupsets. They are produced by manufacturers, independent technical writers, service organizations, and community projects to ensure safe, reliable, and optimized performance of bicycles across casual riding, commuting, racing, touring, and mountain biking.

Purpose and Audience

Primary Purposes

- Provide step-by-step assembly and installation instructions to correctly integrate components onto a bicycle frame.

- Offer maintenance schedules and procedures that extend component life, ensure rider safety, and preserve functionality.

- Furnish troubleshooting guides to diagnose problems quickly and recommend corrective actions.

- Specify technical parameters, tolerances, and torque values necessary for safe operation and compatibility.

- Describe compatibility matrices and part numbering to help riders and technicians select the correct replacement parts.

Intended Audience

- Professional bicycle mechanics and shop technicians who require precise measurements, torque specs, and diagnostic workflows.

- Home mechanics and hobbyists seeking clear instructions to perform routine service such as brake bleed, wheel truing, or drivetrain replacement.

- Enthusiasts and racers looking to optimize component performance, setup, and configuration for specific disciplines.

- Product designers, engineers, and aftermarket manufacturers who need technical benchmarks and interface specifications.

Typical Structure and Contents

Bicycle components manuals generally follow an organized structure that facilitates quick reference and stepwise procedures. A comprehensive manual typically includes:

Title and Identification

A clear title with the component name, model numbers, production date ranges, and applicable serial numbers to ensure the manual matches the part in question.

Safety and Warnings

Detailed safety statements, hazard pictograms, rider weight limits, pressure ranges, and cautions about improper installation. This section highlights critical steps where failure could lead to injury, such as torque specifications, bleed procedures for hydraulic brakes, or torque limits for carbon fiber components.

Tools and Consumables

A list of required tools (torque wrenches, hex keys, pedal spanners, cable cutters, cone wrenches, calipers) and consumables (grease types, threadlocker, hydraulic fluid, sealant) with recommended brands or specifications where relevant.

Technical Specifications

Measurement tables include dimensions, thread sizes, bearing types, torque values, tire and rim compatibility, spoke patterns, and material properties. This section may include exploded diagrams with part numbers for ordering replacements.

Installation and Assembly

Step-by-step procedures for mounting the component to the bicycle, including orientation, alignment, cable routing, torque tightening sequences, and initial setup. Clear sequence numbering and sometimes annotated images or diagrams are provided to reduce ambiguity.

Adjustment and Tuning

Instructions to fine-tune performance after installation—indexing gears, centering calipers, setting sag on suspension, aligning deraileur limit screws, adjusting hydraulic caliper positions, and setting chainline. Many manuals include recommended measurement targets and diagnostic checks to confirm correct setup.

Maintenance and Service Procedures

Routine maintenance intervals (daily, weekly, monthly, annually) and detailed service operations such as brake pad replacement, hydraulic bleed procedures, hub overhaul, bearing replacement, suspension service intervals, and lubrication points. Stepwise teardown and rebuild instructions with recommended parts and replacement kits are common.

Troubleshooting

Common failure modes, symptoms, probable causes, and corrective procedures. For example: squeaking brakes, shifting hesitation, chain drops, bearing play, or hydraulic leaks. Flowchart-style logic or symptom-to-solution tables often improve speed of diagnosis.

Parts and Exploded Diagrams

Exploded views showing each part’s relative position and ordering codes. These diagrams help technicians identify the correct replacement parts and compatible assemblies.

Warranty and Service Information

Manufacturer warranty terms, service-center recommendations, contact information, and guidelines for authorized repairs.

Formats and Delivery Methods

Bicycle component manuals are distributed in multiple formats to meet user needs:

- Printed booklets or leaflets included with the component.

- PDF downloads from manufacturer websites offering searchable text and high-resolution diagrams.

- Interactive online knowledge bases and searchable help centers with videos, animated diagrams, and user forums.

- Mobile apps and digital service manuals that can store service history and push firmware updates for electronic groupsets or smart suspension systems.

Specialized Manual Types

Electronic Groupset Manuals

Electronic shifting systems require additional content such as firmware update procedures, pairing instructions for wireless components, battery replacement and charging, diagnostics for shift performance, error codes, and communication protocols between shifters and derailleurs.

Hydraulic Brake Manuals

Hydraulic systems include specific instructions for safe fluid handling, bleed procedures, bleed kit part numbers, reservoir fill volumes, and contamination avoidance (e.g., avoiding brake fluid contact with paint or carbon surfaces). They emphasize safety when handling DOT or mineral oil fluids.

Suspension Service Manuals

Suspension manuals cover damper and air-sprung service intervals, seal replacement, custom tuning recommendations, pressure charts, and rebound/compression adjustment ranges. They often include guidelines for measuring sag and choosing volume spacers or tokens.

Wheel and Hub Manuals

Wheel manuals address spoke tension patterns, truing tolerances, rim brake track maintenance, tubeless setup and sealant recommendations, and hub bearing preload or freehub service procedures.

Best Practices for Creating and Using Manuals

- Use clear, precise language and standardized terminology to reduce misinterpretation. Visuals should be labeled and aligned with text steps.

- Provide safety-critical steps in bold or distinct callouts and include torque values and measurement targets in tables for quick reference.

- Include checklists for pre-ride inspection and post-service verification to ensure nothing is missed.

- Maintain version control and document revision dates so technicians can confirm they are using the latest safety and compatibility information.

- Encourage hands-on training and certification programs that complement manuals for complex systems (e.g., hydraulic disc brakes or electronic shifting).

Benefits and Value

Well-crafted component manuals improve safety, reduce warranty costs by preventing improper installations, and extend product lifespan through recommended maintenance. For shops, they lower repair times and improve customer satisfaction by standardizing procedures. For riders, they provide confidence in DIY repairs and a deeper understanding of how to optimize performance and reliability.

Common Limitations and Pitfalls

- Outdated manuals may not reflect design changes or firmware updates, creating compatibility issues.

- Poorly translated or diagram-poor manuals increase the risk of incorrect assembly or maintenance.

- Overly technical language can alienate casual riders; balanced manuals often include both quick-start and advanced sections.

Future Trends

- Greater integration of digital content: augmented reality (AR) overlays to guide assembly, video-guided steps, and interactive torque guidance.

- Standardized digital protocols and part-number databases to simplify cross-compatibility checks and parts ordering.

- Expanded use of sensor-driven diagnostics within components that auto-generate service instructions or maintenance alerts.

Conclusion

Bicycle components manuals are essential technical documents that bridge manufacturer intent and real-world use. They encapsulate safety information, precise procedures, technical specifications, troubleshooting guidance, and parts identification—empowering mechanics and riders to maintain, repair, and optimize bicycle systems. High-quality manuals reduce errors, increase component longevity, and contribute to safer, more enjoyable cycling experiences.

Search for 380 Manuals online

Type-in Brand or Model